Fournisseur d'usine de solutions de machines à brocher

U-Bright-Solutions builds numerous standard lines of NEW BROACHING EQUIPMENT and special machines for unique broaching applications.

Fabricants professionnels de machines à brocher

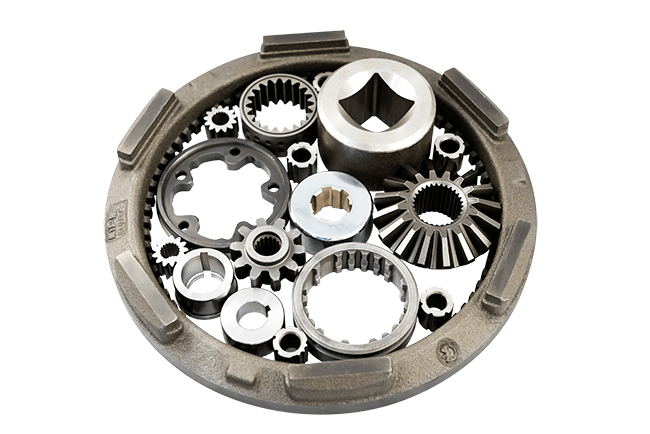

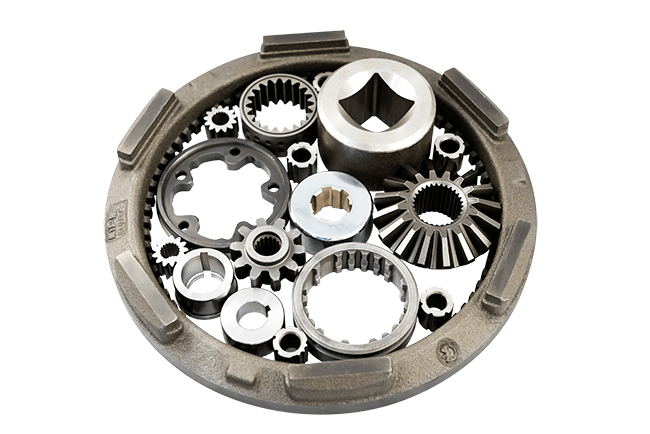

Nous proposons des solutions de brochage uniques pour toute application de brochage de pièces en fonction de nos clients.’ exigences.

Machine à brocher verticale

Machine à brocher servo

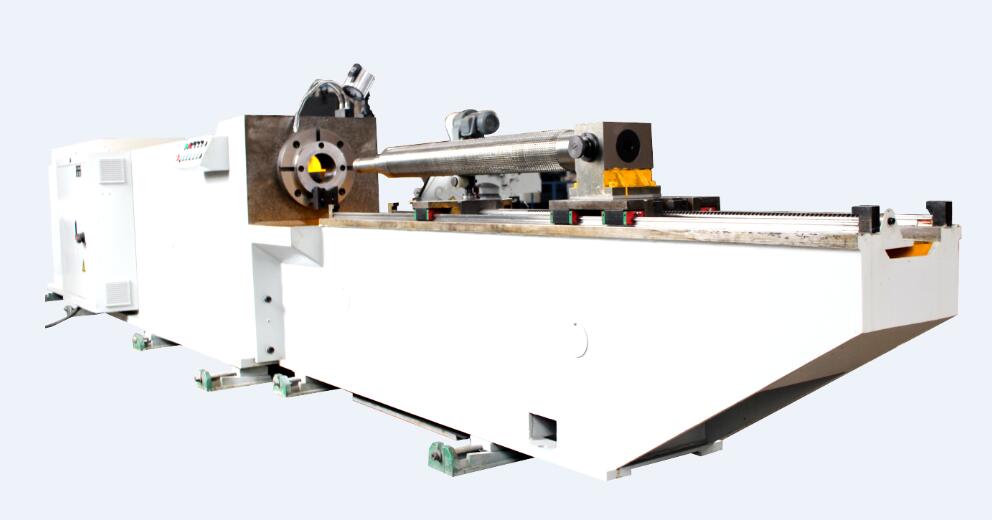

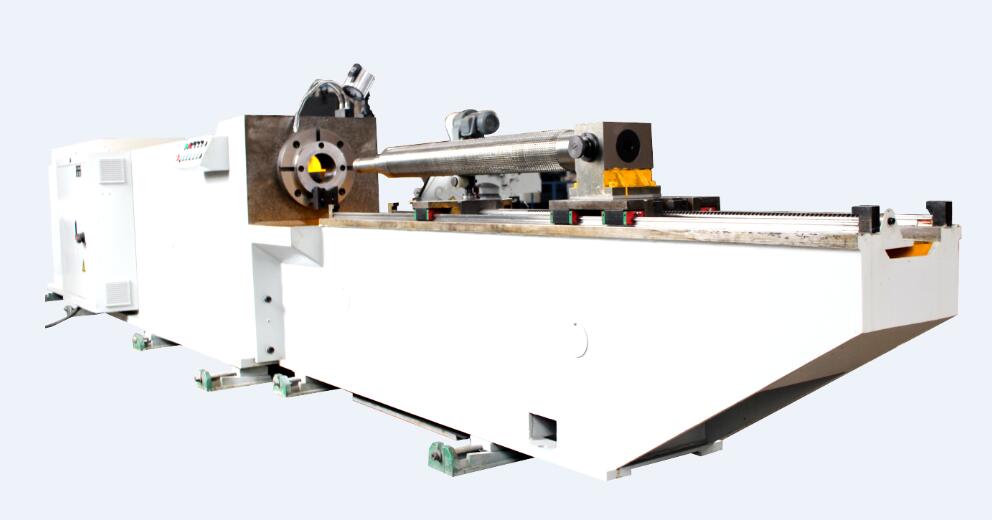

Machine à brocher horizontale

Machine à brocher hélicoïdale

Machine à brocher hydraulique

Machine à brocher CNC

Soulutions Of Broach Machine

Numerous sectors look to BroachingMach as a leader in quality, service, and innovation year after year. Being one of the leading producers of bespoke broaching solutions worldwide makes us proud.

Why Choose BrochingMach?

In this industry, we have over 20 years of expertise. With high quality, reliable performance, and affordable pricing, our products provide a comprehensive selection of broaching options for every workpiece machining application. Our fully automatic broaching machines sold all over the world, making tens of thousands of partners wealthy.

Adequate Equipment

More than 20 kinds of automated broaching machines are professionally designed, manufactured, and sold.

Professional Service

Customers love and trust it because of its great quality, consistent performance, and low pricing.

Advanced Technology

It is an ISO9001:2015 certified corporation that combines cutting-edge local and international technology and concepts.

Rich Experience

Over 20 years of expertise designing, manufacturing, and supplying high-end, high-precision automated broaching equipment.

Professional Broach Machines Order Process

Customers are assisted at every stage of the production process. Each customer is provided a specialized support staff from prototype through delivery to ensure that programs progress smoothly through production.

Provide Drawings Or Samples

Send us workpiece samples or drawings, and supply us with the necessary information.

Technical Quotations

For our broaching machines, our technicians and engineers provide comprehensive technical solutions.

Signing of Contracts

Our technical paperwork and estimate are reviewed and approved by the customer. Sign the contract and pay the deposit.

Production Starts

Broaching machines and all essential accessories will be manufactured.

Pre-shipment Test

The experts will do the final test run of the broaching machine to confirm that it performs steadily and smoothly, that the output meets the requirement, and that the workpiece quality is certified.

Install and Degugging

We provide remote debugging as well as on-site installation, training, and testing services across the world.

Broaching Machines FAQs

Broaching machines and equipment are custom-made for your product. Please contact our sales team and send us designs of broaching machines or product samples for review. We will offer our best advice as well as a detailed technical quotation.

Yes. We provide complete turnkey solutions for broaching machines, clamps, and broaches.

This is dependent on the availability of our inventory and the intricacy of the broaching equipment. Si nous avons en magasin une machine à brocher adaptée, cela prend normalement jusqu'à 15 jours; si une machine à brocher doit être produite, ça prend habituellement 60 à 90 jours du début à la fin. Nous avons besoin 90 à 120 jours pour construire des machines compliquées.

Nous proposons des services de débogage et de support technique à distance. Avant expédition, toutes les machines seront testées et déboguées. Si le client a besoin d'un service porte à porte, nous pouvons envoyer des ingénieurs pour faire le travail, mais le client doit supporter les frais.

La durée de vie de l'outil est bonne lorsque la dureté du produit est inférieure à HRC 25. La durée de vie de l'outil sera considérablement réduite lorsque la dureté est supérieure à HRC 25. Il est recommandé de ne pas aborder si la dureté est supérieure à HRC 32.