Brootsmachines Oplossing Fabrieksleverancier

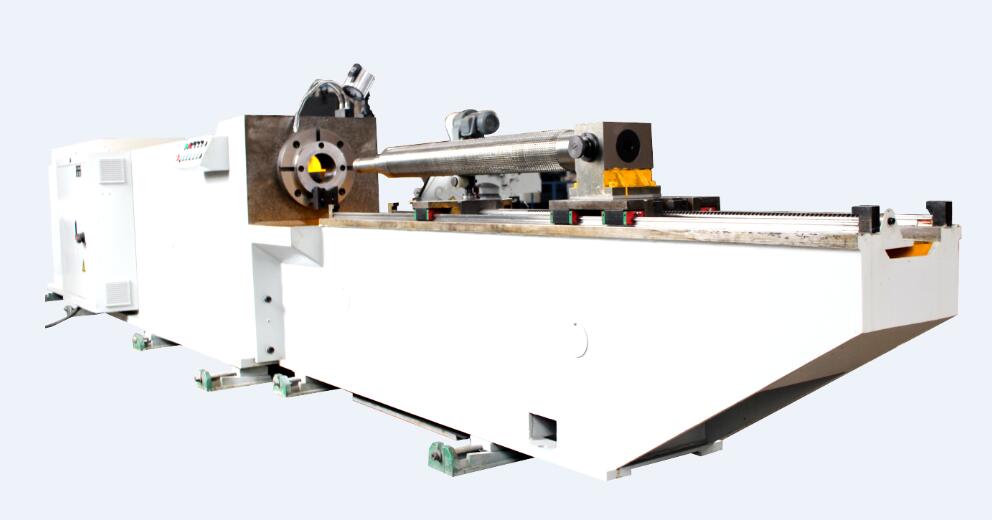

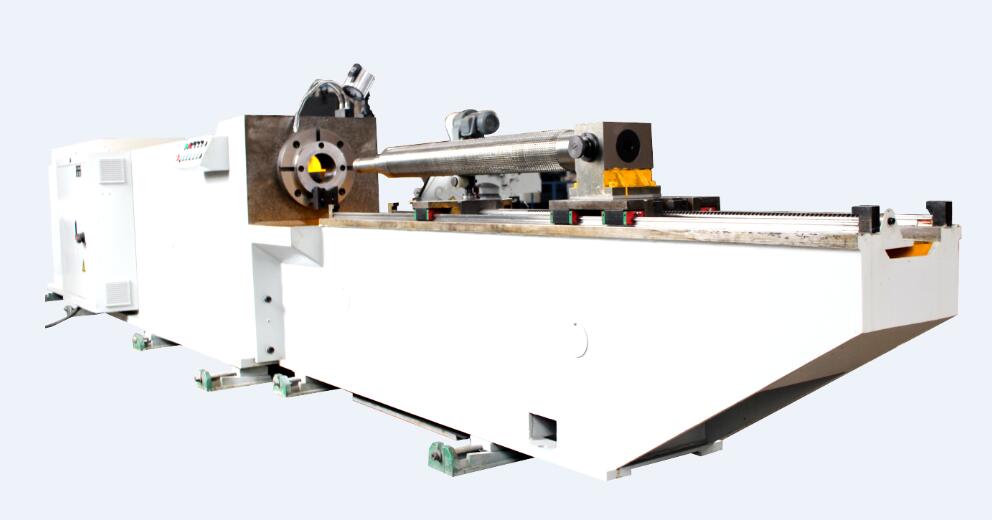

U-Bright-Solutions builds numerous standard lines of NEW BROACHING EQUIPMENT and special machines for unique broaching applications.

Professional Broaching Machine Manufacturers

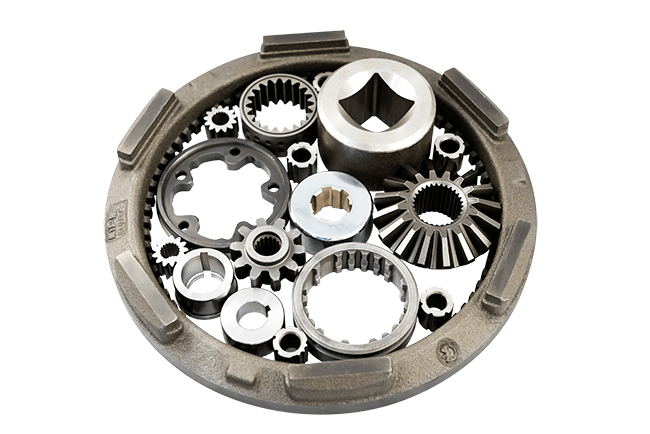

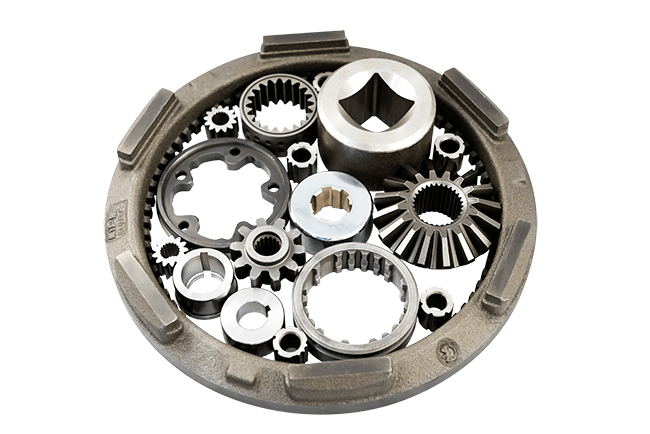

We offer one-stop broaching solutions for any workpiece broaching application based on our customers’ requirements.

Verticale brootsmachine

Servo-brootsmachine

Horizontale brootsmachine

Spiraalvormige brootsmachine

Hydraulische brootsmachine

CNC-freesmachine

Soulutions Of Broach Machine

Numerous sectors look to BroachingMach as a leader in quality, service, and innovation year after year. Being one of the leading producers of bespoke broaching solutions worldwide makes us proud.

Why Choose BrochingMach?

In this industry, we have over 20 years of expertise. With high quality, reliable performance, and affordable pricing, our products provide a comprehensive selection of broaching options for every workpiece machining application. Our fully automatic broaching machines sold all over the world, making tens of thousands of partners wealthy.

Adequate Equipment

More than 20 kinds of automated broaching machines are professionally designed, manufactured, and sold.

Professional Service

Customers love and trust it because of its great quality, consistent performance, and low pricing.

Advanced Technology

It is an ISO9001:2015 certified corporation that combines cutting-edge local and international technology and concepts.

Rich Experience

Over 20 years of expertise designing, manufacturing, and supplying high-end, high-precision automated broaching equipment.

Professional Broach Machines Order Process

Customers are assisted at every stage of the production process. Elke klant krijgt vanaf het prototype tot en met de levering gespecialiseerd ondersteunend personeel om ervoor te zorgen dat de programma's soepel door de productie heen verlopen.

Geef tekeningen of monsters

Stuur ons werkstukmonsters of tekeningen, en bezorg ons de nodige informatie.

Technische offertes

Voor onze brootsmachines, onze technici en ingenieurs bieden uitgebreide technische oplossingen.

Ondertekening van contracten

Ons technisch papierwerk en de schatting worden beoordeeld en goedgekeurd door de klant. Onderteken het contract en betaal de aanbetaling.

De productie begint

Er zullen brootsmachines en alle essentiële accessoires worden vervaardigd.

Test vóór verzending

De experts zullen de laatste testrun van de brootsmachine uitvoeren om te bevestigen dat deze stabiel en soepel presteert, dat de output aan de eisen voldoet, and that the workpiece quality is certified.

Install and Degugging

We provide remote debugging as well as on-site installation, training, and testing services across the world.

Broaching Machines FAQs

Broaching machines and equipment are custom-made for your product. Please contact our sales team and send us designs of broaching machines or product samples for review. We will offer our best advice as well as a detailed technical quotation.

Yes. We provide complete turnkey solutions for broaching machines, clamps, and broaches.

This is dependent on the availability of our inventory and the intricacy of the broaching equipment. If we have a suitable broaching machine in store, it normally takes up to 15 days; if a broaching machine needs to be produced, it usually takes 60 to 90 days from start to completion. We need 90 to 120 days to build complicated machinery.

We offer remote debugging and technical support services. Before shipment, all machines will be tested and debugged. If the customer requires door-to-door service, we can send engineers to do the job, but the customer must bear the expense.

Tool life is good when the product hardness is less than HRC 25. Tool life will be greatly decreased when the hardness is higher than HRC 25. The recommendation is not to broach if the hardness is higher than HRC 32.