Broach Tools

We’re known for providing our clients with a complete line of broaching tools for their production needs—including even the most demanding of applications.

We Are The Broaching Tool Experts

We manufacture and recondition all types of broaches. A well produced broach produces a flawless quality item with exact shape, increases the tool’s lifetime, and, most importantly, saves money. All of our broaching tools are of the highest quality.

Round Broaches

Round broaches are precision tools used in machining to create circular holes in a workpiece.

Spline Broaches

Spline broaches are used to create a splined shaft, which is a type of smooth, sturdy drive mechanism that allows for the transfer of torque.

Rectangular Broaches

Rectangular broaches are the most popular form of broach. This is because rectangular broaches give more precision when cutting objects with complicated contours.

Keyway Broaches

A keyway broach is one of the most popular types of broaches, and they are widely used in a variety of industrial applications.

Involute Broaches

Involute Broaches are one of the most popular types of broaches, due to their simple and effective design.

Broach Tooling Design

We use the latest state-of-the-art programs and software, so you know you can rely on our end products.

Professional Broaching Machine Manufacturers

We offer one-stop broaching solutions for any workpiece broaching application based on our customers’ requirements.

Vertical Broaching Machine

Servo Broaching Machine

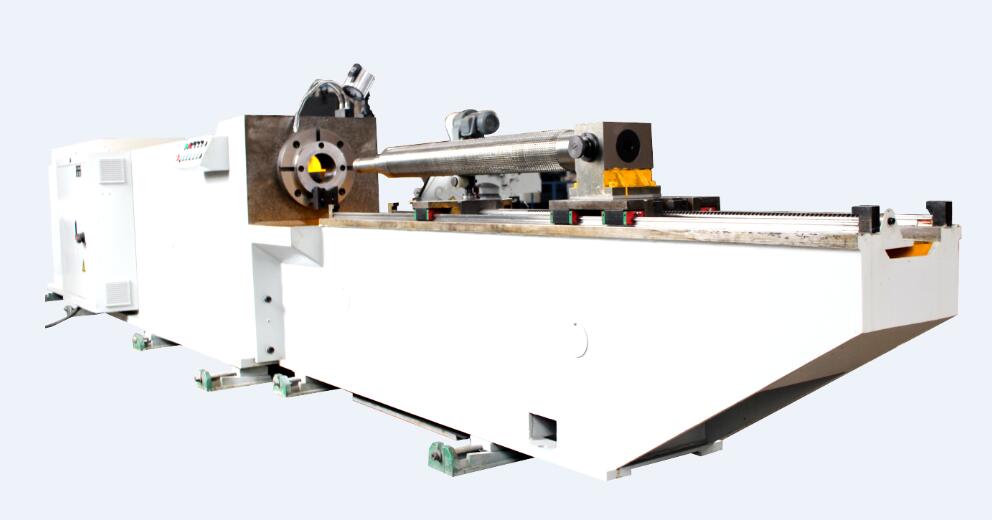

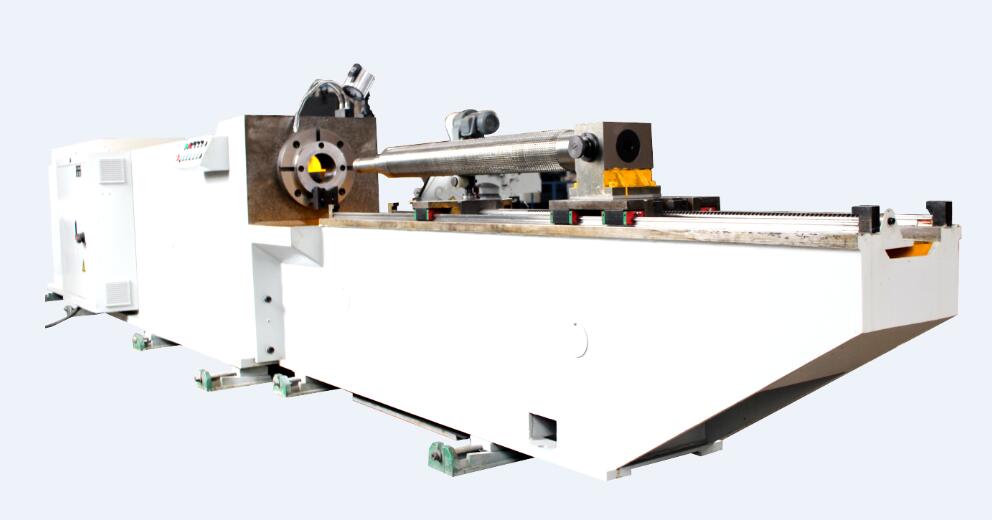

Horizontal Broaching Machine

Helical Broaching Machine

Hydraulic Broaching Machine